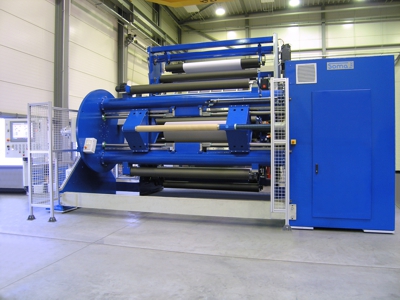

New designed shaftless turret rewinder AW-1500 S

Besides the proven design of the turret rewinder AW-1500 S, where the chucks are arranged movable within the side frames, now a new design is available. Here the chucks are directly movable on the indexing system.

By this new design a greater flexibility at the support of different core lengths is achieved and therefore the winder can be adapted even better to individual production conditions. The handling of finished reels and feeding of new empty cores is easily and quickly possible by the shaftless design.

New details

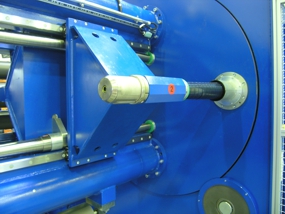

The chucks for supporting the cores are arranged on chucking slides, which are mounted between the indexing disks on linear slides and which can be moved motorized to the desired working width. Thereby the chucks are moved apart and together by a ball-type linear drive. For alignment to the running web the clamped empty core can be moved sideways additionally.

By an integrated clamping mechanism the chucking heads cannot slip within the core, because the clamping force within the chucking heads is increased depending on the actual torque of the winder.

The idler rolls on the indexing system are motor-driven, so that they do not influence the web when they touch the web surface during indexing.

Driving of the winding stations is done from the winding motors located stationary within the winder's side frame. By this arrangement only the auxiliary drives on the indexing system have to be supplied via a slip ring assembly.

Proven technique

Of course the new AW-1500 S is equipped with the reliable high speed reel change system TAC, which distinguishes with a rectangular cross cut up to winding speeds of 600 m/min (2000 fpm). This is achieved by a electrical-mechanical loading of the serrated cross cutting knife. Lay-on of the web is done automatically onto adhesive prepared cores. The solid and hard-wearing design ensures a high production safety.

Arrangement of the the reel change system TAC can be optionally from top or from bottom, so that the web upper side is alternatively wound on outside or on inside of the reel. Also two systems can be arranged within one winding machine to allow both winding directions electively, depending on the production requirements.

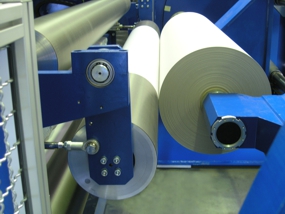

The contact roll unit is designed for contact and gap winding mode, so that the applicable winding mode can be selected due to production requirements.The contact roll is pneumatically loaded and arranged within a servo-driven contact roll slide. By this arrangement the contact roll can either be pressed with a defined contact pressure against the reel or the contact roll moves backwards in a constant distance to the wound reel. The design of the contact roll is made for both winding directions, i.e. the web path is chosen in a way, that an influence the contact pressure by the winding tension is excluded.

For separation of the tension from the production line a pull roll system is arranged at the winder's inlet. This pull roll system consists of a driven ceramic-coated pull roll and a pneumatically engaged rubberized pressure roll. By the s-shaped wrapping of the web around the rolls also a high tension difference is safely separated an the web is transported without slippage.

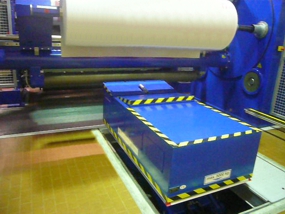

Easy unloading of the wound reel is done by a lifting table, which unloads the reel directly from the chucks of the winder's unloading position. The reel is placed directly on the floor or on a pallet.

This basic concept of the turret rewinder AW-1500 S can be customized depending on the actual request. The dimensions (working width, winding diameter, speed) as well as the features (spreader rolls, de-ionization, edge trimming, etc.) can be adapted and added to get a winder exactly fitting to your demand.

Reel change system TAC arranged in lower position...

Reel change system TAC arranged in lower position... ...or in upper position

...or in upper position Contact roll shortly after reel change

Contact roll shortly after reel change Lifting table for easy reel unloading

Lifting table for easy reel unloading