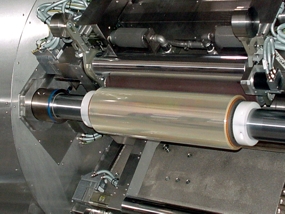

SOMATEC high speed turret winder HAW

The SOMATEC high speed turret winder HAW is a non-stop winder for highest demands at the in-line reel change. So perfect winding of sensitive materials as damageable plastic films, decor papers or nonwovens is possible up to a speed of 1500 m/min (4900 ft/min). Reel change is done at full web speed. In contrast to the standard turret winder principle the winding geometry is kept constant in optimum condition and the turret movement has no negative influence to the winding result.

A turret winder is a standard solution for an automatic reel change for center driven winding. But the good winding geometry is disturbed when the indexing movement starts as the optimum winding position at the contact roll has to be left. Auxiliary devices as rider rolls or an indexing contact roll will help here only partly and will be no entire replacement for the contact roll even during winding with highest speeds.

But this is different at the high speed turret winder HAW: Each winding station has its own contact roll system and its own reel change system. So the indexing movement cannot disturb the winding process any more and winding is perfect from the first to the last layer. The reel change is performed at full winding speed with a rectangular cross cut onto adhesive prepared cores. These can be supported either shaftless or on winding shafts - depending on the request. When using winding shafts the integrated winding shaft handling system - also developed by SOMATEC - is an interesting alternative for the traditional shaft handling outside of the machine. Here the shafts remains within the winder and an additional external shaft handling is not necessary.

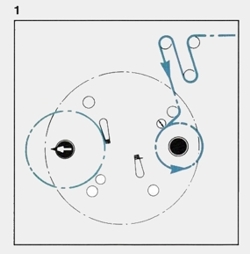

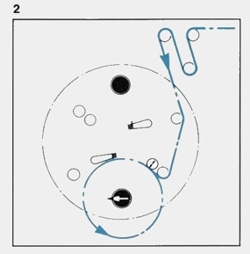

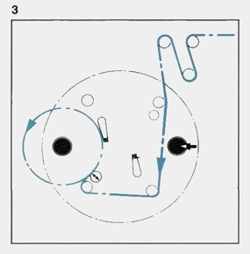

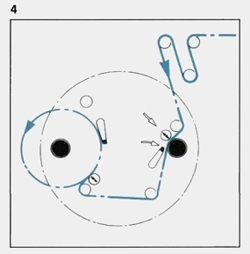

And these are the steps during the reel change of the high speed turret winder HAW:

Overview of the advantages:

- Fully automatic reel change at highest web speeds up to 1500 m/min (4900 ft/min)

- Best winding results from the first to the last layer by optimal winding conditions even during indexing and during reel change cycle

- precise contact roll pressure control

- Optional automatic reel handling and winding shaft handling available