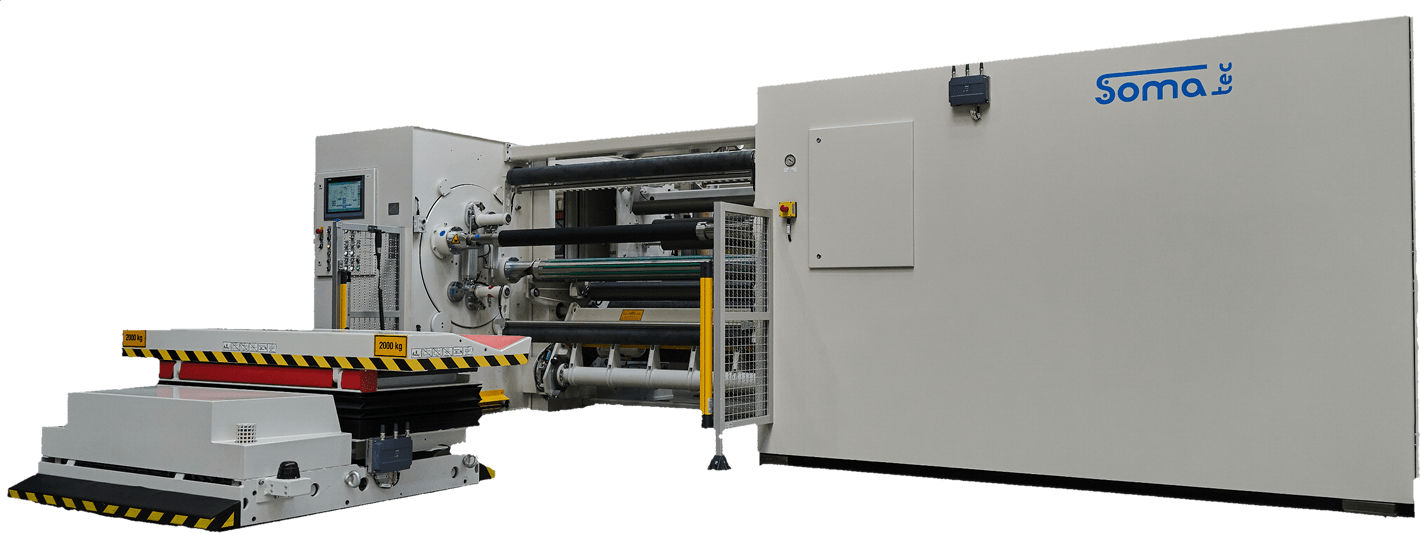

Automatic turret winder with integrated winding shaft pulling system ATW - I und ATW - IG

Practical and functional. Versatile in use. Already sold over 50 times worldwide.

The turret winder series was mainly developed for use in film and nonwoven production. Thanks to its modular design, it can be ideally adapted to any production situation. This includes the different sizes and the different automatic roll changing systems, as well as slitting systems and handling components that can be integrated into the machine concept.

The ATW - I turret winder is particularly characterized by its integrated winding shaft handling. The winding shafts always remain in the machine, so that the finished roll handling is significantly simplified. In addition, the ATW - IG turret winder is specially designed for the largest roll diameters - up to 2,400 mm - so that it can be used primarily in nonwoven and glass fleece production.

Even special requirements are not a problem - our specialists develop individual solutions for you based on their many years of know-how.

Diverse equipment options

For perfect winding results:

- Scissor cut or blade cut

- Expansion shaft mode with friction winding option

- Antistatic equipment

- Driven Lay-on rolls

- Optional contact or gap winding

- Both winding directions possible

For high efficiency:

- Edge trim suction or pull-roll

- Short roll Set-Up

- Chucks for steel core

- Intergrated winding shaft pulling system

- Roll unloading cart with up to 25m driving range

- Automatic reel change system TAC oder NTC