Unwind and rewind stations for Re-reeler and Slitter-Rewinder

The following solutions are possible for the unwind and rewind stations of Re-reeler and Slitter-Rewinder:

- Reel support with winding shafts or shaftless via expanding chucking heads

- Hydraulically or motorized operated lift-in or deposit of the reels

- Unwind stand with pneumatic brake or regenerative brake

- Edge guiding or steering system either by sideways movement of the unwind or by a pivoting frame

- Splice table for a safe web splicing after the unwind

- Multiple web winding -depending on the material type -on one common shaft or two friction winding shafts

Additionally the following devices for web and reel handling are available:

- Web thread-in devices

- Reel loading or unloading carts

- Winding shaft handling systems

Examples

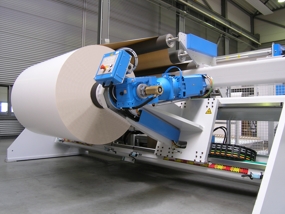

Shaftless unwind station, hydraulically swivel mounted for reel lift-in from floor level

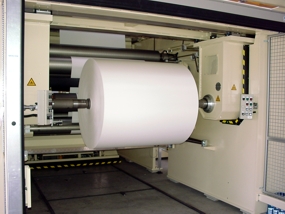

Shaftless unwind station with contact roll for adhesive films, motorized liftable for reel support from a trough

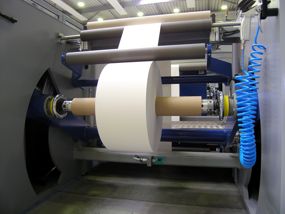

Unwinding station with swiveling winding shaft shaft support

Vacuum splice table for a safe web splicing

Splice table with pneumatically operated clamping rolls

Pivoting frame for edge guiding underneath a platform

Rewind station for shaftless rewinding and for winding on winding shafts

Overhead mounted rewind station for shaftless reel support

Rewinding station with swiveling winding shaft shaft support and contact roll

2-station rewinder with friction winding shafts

Automated web thread-in device

Automatic reel handling with elevator cart