News from SOMATEC

We would like to take this opportunity to express our sincere thanks to our customers, partners and employees.

Regardless if tension sensitive nonwovens, thin plastic films or fast running paper webs – SOMATEC Unwinders are the right solution when these products have to be fed to any finishing or converting process.

Wherever flat webs have to be wound after a production- or finishing process, SOMATEC's winders are the first choice.

Many different tasks require unwinding and rewinding of flat webs. Regardless if this is for slitting of individual webs, for web inspection or for further finishing processes of the product, SOMATEC offers for each of these tasks an individual solution dependent of the actual requirement.

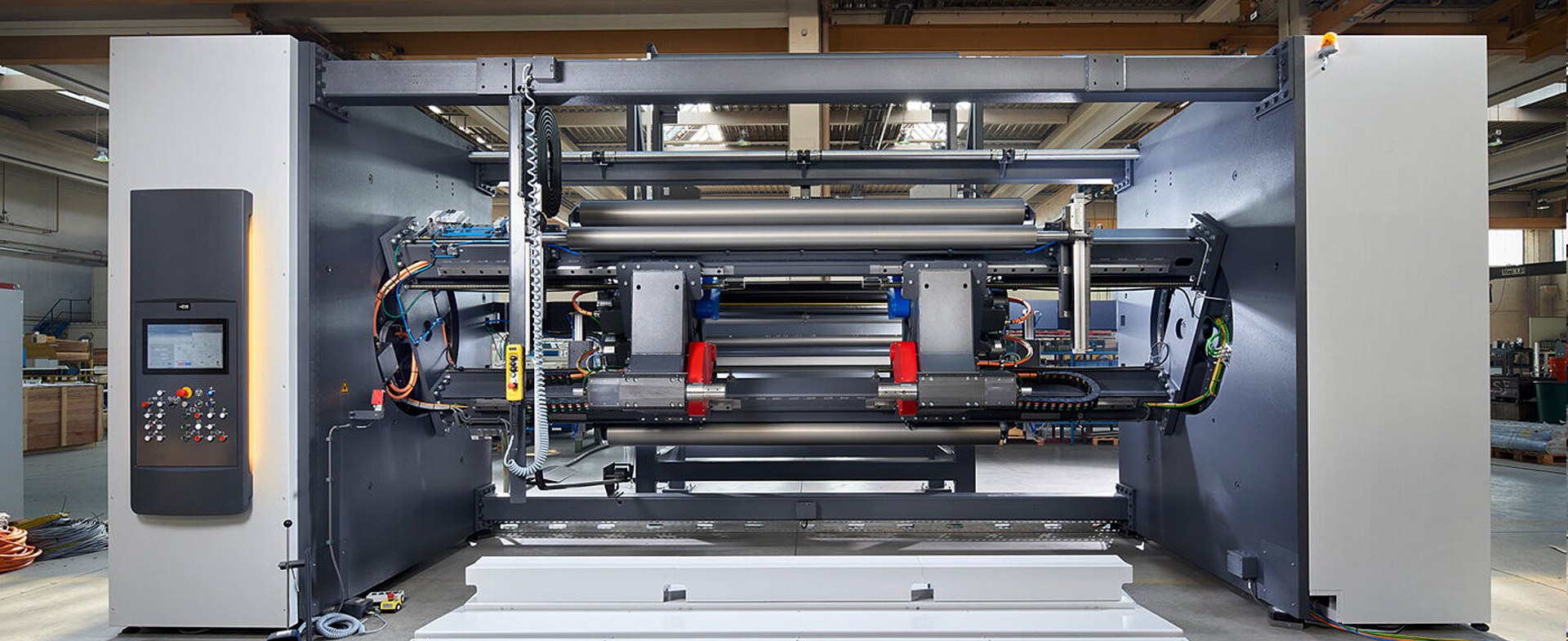

If a roll change shall or have to be done at machine stop during unwinding or rewinding processes an accumulator ensures the continuous web transport to or from the production line. For these tasks SOMATEC offers the most different accumulator designs and sizes.

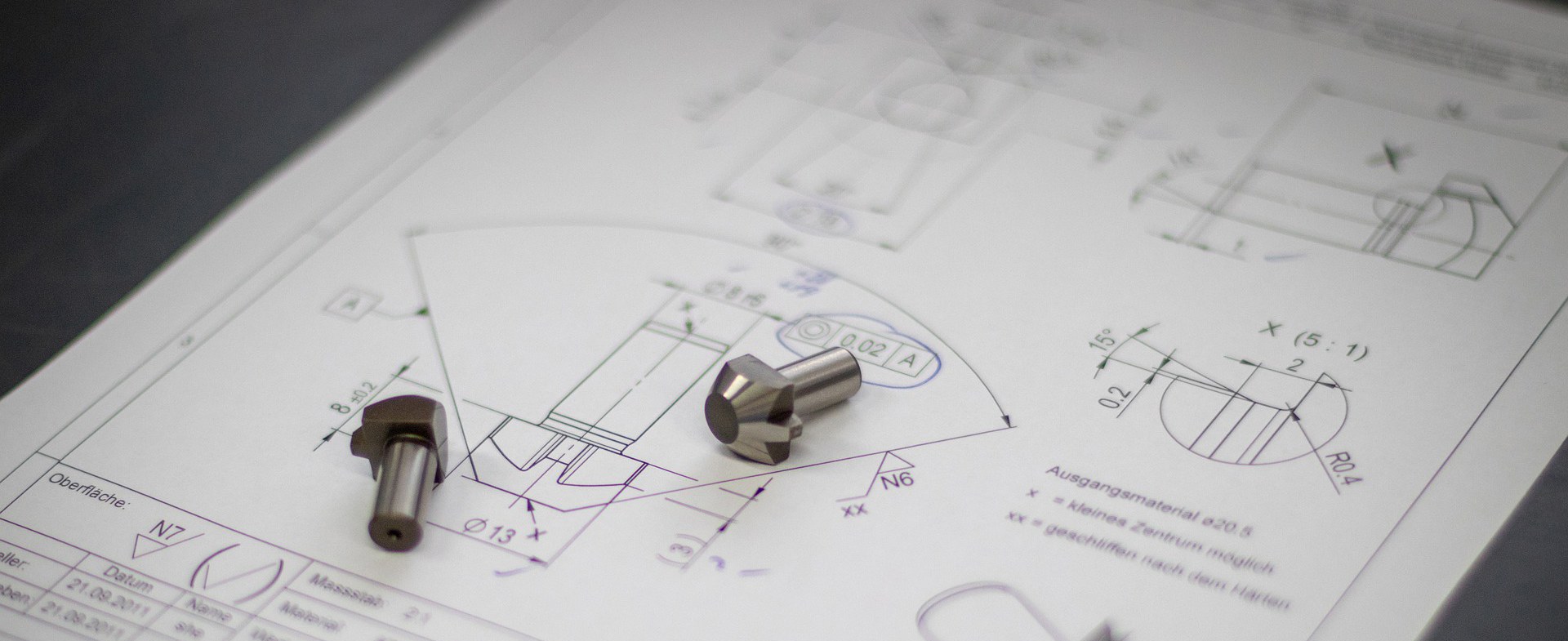

These are individual function groups, which are arranged and operated relatively independent from the main machine or which will be added later to the main machine.