07/19/23

SOMATEC reel changing system TAC - Fast, simple and precise

You want to wind soft films at high speed and quality? Then the SOMATEC automatic reel changing system TAC is the ideal solution for you. The system offers you numerous advantages that save you time, material and costs.

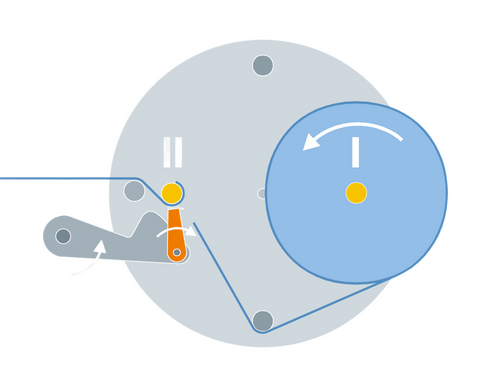

The TAC system changes the reels fully automatically without you having to intervene. The adhesive strip guarantees easy and safe winding of the foil without the cores touching or damaging the running web. This avoids material losses and quality defects. In addition, you save adhesive tape, because with 3" cores, one longitudinal strip of adhesive tape is sufficient if the speed is less than 150 m/min. The system automatically detects where the adhesive strip is on the sleeve and places the foil exactly on it.

The TAC system changes the reels fully automatically without you having to intervene. The adhesive strip guarantees easy and safe winding of the foil without the cores touching or damaging the running web. This avoids material losses and quality defects. In addition, you save adhesive tape, because with 3" cores, one longitudinal strip of adhesive tape is sufficient if the speed is less than 150 m/min. The system automatically detects where the adhesive strip is on the sleeve and places the foil exactly on it.The foil is cut at right angles with a serrated cross-cutting knife that is electro-mechanically pre-tensioned. This ensures a clean and precise cut that does not damage the foil. The tension is controlled during the entire reel change process so that the foil is not stressed or stretched. The result is perfectly wound reels with no wrapping creases or wrinkles.

The system can be flexibly adapted to your needs. You can place it at the top or bottom of the machine, depending on whether you want the top of the web to be on the inside or outside of the roll. If you want to use both winding directions, you can also install two systems in one machine. This increases your productivity and flexibility.

The system can be flexibly adapted to your needs. You can place it at the top or bottom of the machine, depending on whether you want the top of the web to be on the inside or outside of the roll. If you want to use both winding directions, you can also install two systems in one machine. This increases your productivity and flexibility.With the automatic SOMATEC reel change system TAC you can wind soft films at a speed of up to 600 m/min. The system is robust, low-wear and low-maintenance. It offers you high production reliability and quality.

Contact us today and learn more about the SOMATEC reel changing system TAC.

This video will be loaded from Google YouTube.

Their privacy policy applies.

Their privacy policy applies.