11/17/25

Innovative test cutting device developed at SOMATEC as part of a bachelor's thesis

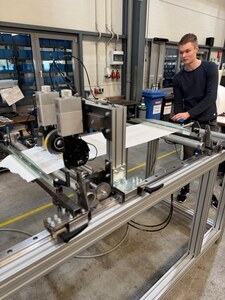

As part of a bachelor's thesis on the topic of ‘Design of a cutting test station for the longitudinal cutting of web-shaped materials’, a novel test cutting device was designed and successfully implemented at SOMATEC Sondermaschinen GmbH. The aim of the project was to develop a flexible, practical system that would enable different cutting processes and material properties to be examined under realistic conditions.

Project content

The test station developed is used to analyse the cuttability of a wide variety of materials and allows direct comparison of several cutting types:- Blade cut

- Heated blade cut

- Crush cut

- Shear cut

The test material can have dimensions of up to 500 mm x 1450 mm. A pneumatic clamping device ensures precise and reproducible fixation of the material with individually adjustable tensile force – an essential prerequisite for reliable test results.

Technical features

The design impresses with a range of technical highlights that enable flexible and practical use:Quick tool change thanks to variable knife holders with dovetail mountings

Freely adjustable process parameters, based on the adjustment logic of modern winding machines

Universal material compatibility – from paper and films to complex composites

Practical benefits and added value

This test cutting device provides SOMATEC with a powerful tool for the further development and optimisation of cutting processes.The system allows precise analysis of material and cutting behaviour, testing of new cutting technologies and simulation of customer-specific requirements under realistic conditions. It thus makes a valuable contribution to quality assurance and product development at SOMATEC.