Easy core preparation for an optimal automatic reel start

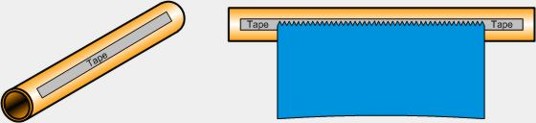

The preparation of a core is often a complicated task at production preparation. SOMATEC has now developed a way, where only one single stripe of adhesive tape has to be applied parallel to the core. This is time and cost saving and will give a perfect beginning of the new reel.

This traditional way of core preparation you know: The core is completely spiral wound with adhesive tape, where often tape with only one adhesive side is used. There the core first have to be wrapped at one side with the adhesive side to the core, then the tape is turned 180° and the whole core is wrapped spirally with the tape with the adhesive side outside. At least the tape is turned back so that the adhesive side is again onto the core and the tape is fixed at the other core end by wrapping the tape around the core. The results: High consumption of adhesive tape, improper lay-on of the web due to the uneven adhesive tape and uneasy handling.

All this you will save with the new way of the SOMATEC preparation process. Here only one single strip of adhesive tape has to be applied parallel to the core and that's it! The leading edge of the new reel is automatically fixed onto this tape by the reliable SOMATEC reel change system TAC.

Thereby the serrated rectangular cut leading edge is exactly and safely positioned onto the tape. Foldover edges or single teeth are a thing of the past. Compared with the traditional way of core preparation there are no marks within the web caused by uneven adhesive tape.

Thereby the serrated rectangular cut leading edge is exactly and safely positioned onto the tape. Foldover edges or single teeth are a thing of the past. Compared with the traditional way of core preparation there are no marks within the web caused by uneven adhesive tape.

SOMATEC's new way of core preparation is working up to 150 m/min with 3" cores and corresponding faster with bigger core diameters.

Read more about SOMATEC's automatic turret winder ATW and the reel change system TAC here.