SOMATEC Load relieving roll

Efficient winding means, to wind the product up to a maximum diameter onto a minimum core diameter without any loss of quality. Unfortunately there are physical limitations, when high reel weights in combination with small core diameters will result in a too high deflection of the winding shaft. A not edge-true winding is the result, especially when winding multiple webs on one common shaft.

A solution for this problem is the SOMATEC load relieving shaft, which supports the reel from below and minimizes the otherwise occurring deflection. Additionally the winding result can be optimized by the motor-drive of the load relieving roll.

The load relieving roll can be installed within various types of winding machines. This can be either continuous running in-line winders and well as re-reelers and slitters for off-line operation.

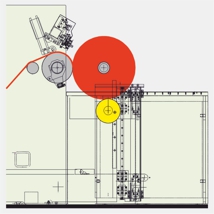

Arrangement within turret winders

Within a turret rewinder the load relieving roll is mounted below the unloading winding position. So up to a certain diameter the reel is wound in normal winding position and is then indexed in unloading position for winding up to maximum diameter with the support of the load relieving roll. This principle is tried and test since many years for winding of heavy paper reels. Here e.g. reel weigths of 3,5 tons and more than 2 m working width are wound on 4" winding shafts.

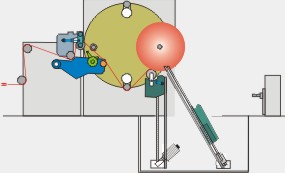

Arrangement within surface winders

Surface winders can be equipped with a load relieving roll which is arranged within the winding slide. Here it is moving together with the increasing reel diameter. The support pressure of the load relieving roll is selectable, so that the amount of compression within the material by the support pressure can be influenced. The motor drive of the roll not only compensates the mechanical friction of the roll but also gives a positive influence of the winding result by a selectable variable speed of the roll. Depending of the product type and the need the function of the load relieving roll can be switched on and off.

Surface winder with load relieving roll