Winding modes

The winding mode describes the principle of driving a reel. This can be done from the center or from the surface of the reel.

Driving a reel can be done either from the center or from the surface. In practice there are corresponding machine designs which allows partially also a combination of both driving methods.

At a center winder the winding torque is transmitted from the support of the winder trough possibly a winding shaft and the core to the first layer of the reel. From there the torque is transmitted from layer to layer up to the last outer layer. So the wound material must be suitable for this winding principle. Very tension sensitive and soft materials (e.g. nonwoven) does not allow this and therefore must be driven from the surface of the reel.

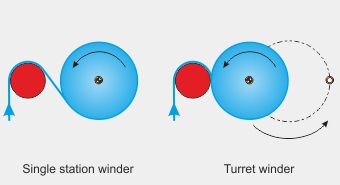

Examples for center winders

At a surface winder driving of the reel is done always from the last outer layer of the reel. Transmission of the torque is done from a driven roll and the pressure between this roll and the reel. Depending on the design of the winder either the roll can be pressed against the reel or vice versa. At a so called carry or support roll winder the pressure is created by the weight of the increasing reel laying on the driven support rolls.

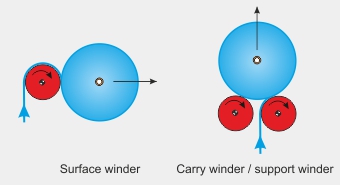

Examples for surface winders