Winding encyclopedia

Here important terms of the winding technique were explained in alphabetical order. If you will have nevertheless still open questions, so we will answer these - please contact us.

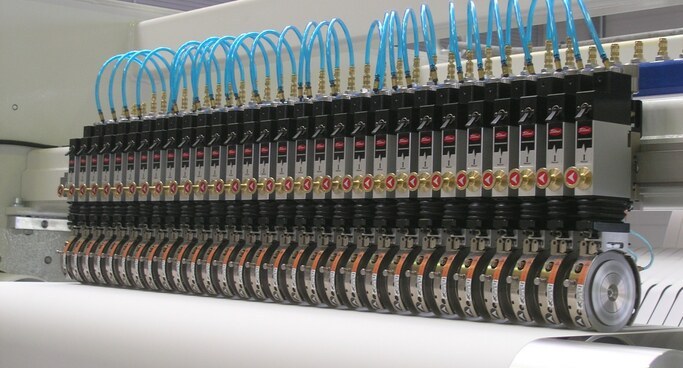

At scissors cutting the web is slit for further processing by a circular knife, which is pressed against an also circular counter knife.

At score cutting the web is slit for further processing by a circular knife, which is pressed against a hardened shaft..

Slitting of a web is done for cutting of edge trims and for dividing the whole web into several single webs. Depending on the type of material and the material characteristics different cutting principles are used.

Spreader rolls are used for smoothing of the web and for separation after slitting of individual webs.

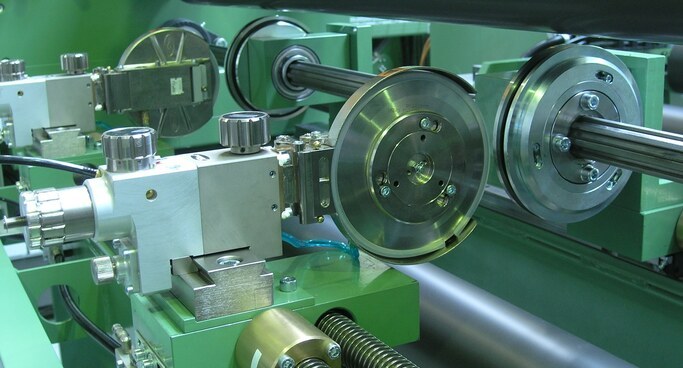

A tension control roll is needed for measuring the tension within a web and can be used for controlling of a following drive (pull rolls, winder).

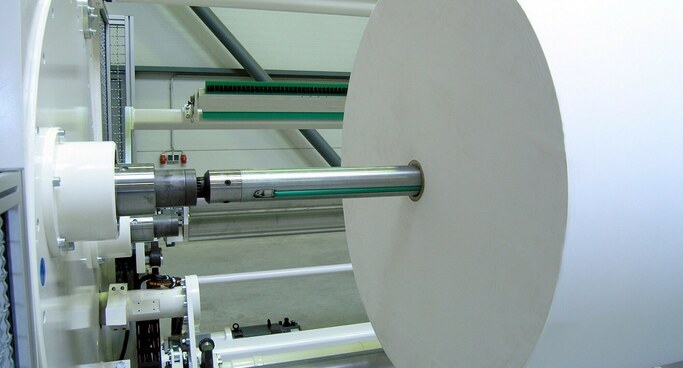

Web processing means the performing of the web to a desired final width and/or length.

The web will be transported within a winding machine or production line by pull rolls. For the web transport a constant speed and a defined tension are necessary within the web.

The winding mode describes the principle of driving a reel. This can be done from the center or from the surface of the reel.